2" Granadillo Pre-Cut Squares

SKU: ts-gran$12.00 ea.

mix/match strips and squares

(48 U.S. Ground)

Why Choose Granadillo?

Granadillo will enchant your creativity with its bold purplish color and beautiful rosewood-like patterns. It's a hard wood that will take an ultra-fine polish and will steal the show in your decorative projects.

Get ready to work with the finest wood squares you've ever seen, they're ready to be turned into whatever you can imagine, such as furniture parts, table legs, small accessories, handles, artwork and other fine woodworking projects.

| Thickness | 1-3/4" (≈ 1-3/4" approx) |

| Width | 1-3/4" |

| Length | 12", 18", or 30" |

| Grade | Air dried and end-waxed |

Woodworkers Also Recommend These

5.25

lbs /Bd. Ft.Wood Texture

Ease of Finishing

Dark brown to red to orange to purple

These trees are reported to reach heights of 80 feet with trunk diameters of 29-42". The buttressed trees develop straight and well-formed boles, that are often clear to 60 feet.

Coyote, Cocobolo, Granadillo, Guayacan trebol, Jacaranda do brejo, Koenatepi, Macacauba, Macawood, Trebal, Trebol

Pool cues, musical instruments, inlay, turnings, veneer

Look beautiful

Great stuff

Solid winner!

The Joys of Building with Great Woods

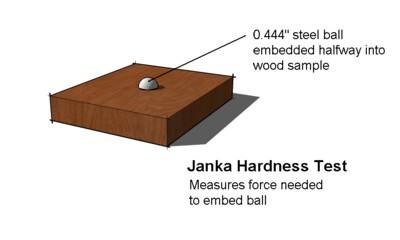

Understanding hardwood lumber starts right here with these wacky fractions.

If you're expecting perfect clear lumber 100% of the time, you're in for a surprise. Here's a summary of the hardwood lumber grades and what to expect from them.

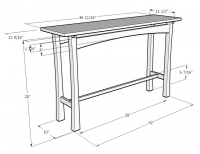

Board feet isn't your everyday kind of math, but these three simple steps make it easy to figure out your project.

Here's a handy (and free) Excel worksheet that helps you estimate the lumber needs for your project.

Are woods poisonous? Hazardous to use in cutting boards or baby cribs? Find out here.

Wood is like a sponge, and it's always in a state of absorbing or releasing moisture to stay equalized with its environment. The problem with that is it also swells and shrinks. Here's what you need to know to protect your project.