Here's What to Expect from Lumber at Woodworkers Source

Hardwoods Come in Random Widths & Lengths

In hardwoods, thickness is the only standardized dimension. Widths and lengths are stocked in random dimensions. Generally the range is 4" to 12" wide, 6' to 14' long.

So how do you get the sizes you want?

In woodworking, you cut and/or glue to create the sizes you need.If you're ordering online, you can request minimum widths or lengths so that the lumber you buy is larger than your required minimum sizes.

If you visit us in person, you simply pick out the boards that you think will work the best for you.

Scroll down to the FAQs at bottom to learn more.

Why are sizes random?

Lumber is sawn from logs to get the most yield, and since trees are round and irregular the lumber comes off in random sizes. Randomly sized lumber means it doesn't cost nearly as much as lumber that's been manufactured to uniform sizes - there's less waste, less labor, less processing to create random sized lumber.Your lumber budget goes a lot farther with random sized raw material.

When you're making custom furniture and home furnishings, random sized lumber means you get to be more selective of grain and color, and have more control over your yield.

We Stock Surfaced (S2S) Lumber

Planed smooth on 2 sides (the face and the back)

Edges are rough sawn

You may choose to have one edge ripped clean at the time of ordering

Surfaced lumber is a lot easier for you to see the grain and put to use right away.

Rough lumber, on the other hand, is difficult to see the grain, requires more work to get it ready for a project, and is marked by the cupping, twisting, and warping that takes place during the drying process. We've had our rough sawn lumber planed smooth to make it easier on you.

Our Lumber Is Kiln Dried & Protected

We stock our lumber in a controlled warehouse, keeping the wood out of the sun and rain. It's also neatly stacked and frequently culled to ensure the lumber is looking its best.

What does kiln drying do? It's a process that brings lumber to its most stable condition.

Logs contain a high percentage of water therefore freshly sawn lumber is wet (also called "green"). As it dries, it shrinks, and as it shrinks it cracks, cups, twists and distorts just like a kitchen sponge does as it dries out. Kiln drying is a controlled process that extracts this moisture out of wood so that it warps, cups, twists, and cracks the absolute least. The result is very stable lumber - though kiln dried lumber still can cup or warp, it is wood after all, the severity is reduced.

83%+ of Defect-Free with Select & Better Grade

Select & Better is an official industry grade that contains a mix of the best 3 lumber grades that are available in the marketplace. Here are the basic requirements:

Provide at least 83% clear cuttings on one side

Board size must be at least 4" wide and 6' long

Select & Better graded lumber is a nice value for the craftsman because it strikes a balance between cost and clear wood.

Some woods are not available as a Select or Better grade. When this is the case, it's indicated on the ordering page for the wood in question.

Lumber Ordering

Buying lumber by the board foot is an exercise in estimation.

(What's a board foot? Start Here)

Once you figure out how much board footage your project requires, you can then come up with an approximation of how much you should buy.

Basics of Estimating Board Feet for Your Project

1. Start with a project idea, plan or sketch

2. Make a parts list, and determine the board footage of each part

3. Add it up, then estimate a waste factor

VIDEO TIPS!

3 Steps You Can Use to Figure Out Board Feet for a Project

Check out this tutorial to learn all about how to estimate board footage for a whole project.

First we need to know if you're looking to buy sizes already cut to size, or if you are looking to buy sizes that will yield what you want to cut.

Choose from 2 different ways to get the sizes you want:

1. Custom Hand Selection

This means you'll do your own cutting/gluing/sizing, but we select wood to meet or exceed your needs.

- We pull the lumber to be larger than the sizes you need

- You would do the final cutting and/or gluing

- Boards would come in random widths/lengths, but large enough to yield what you need

- Selection fee of $1.00 /bd ft. applies

You can order right online for this option. Use our "Selection Requests" box on the ordering page to tell us what you need to achieve.

2. Custom Cutting and Milling

This means We do the cutting for you. Some of the services we can do include:

- Cutting to exact sizes within 1/16" tolerances

- Gluing up solid wood panels for table tops, stair treads, etc.

- Resawing for bookmatched panels or thin stock

- Creating thin lumber 1/8", 1/4", 1/2", 3/16" etc.

To do this, call or email to have a quote worked up for you.

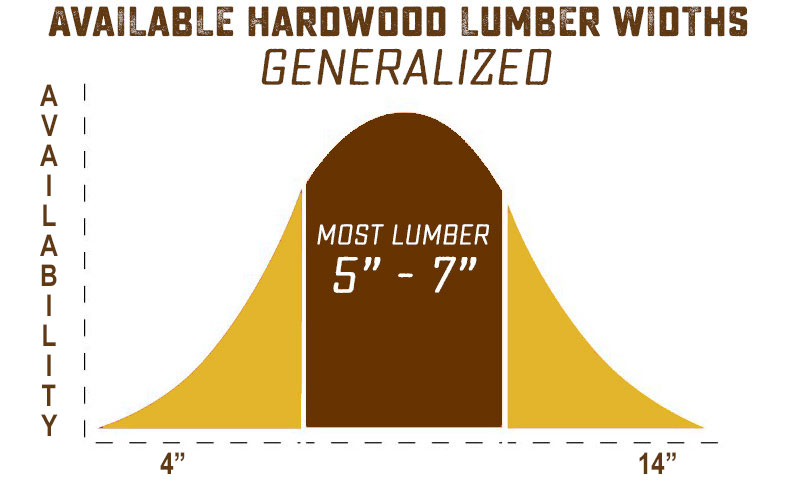

Here's a visualization of what you cna expect in lumber widths. Most are 5" to 7". Very little is 12" or wider, and nothing is narrower than 4".

Picture a bell curve. Most widths are 5" to 7" in most woods in most thicknesses. (There are always exceptions!)

If you read our explanation of lumber grades, you'll know that we carry the "Upper" grades and that means there's nothing less than 4" wide except in unusual circumstances.

What about the widest? The amount of wider stuff starts to decline once we start talking about 8" tapering down to where there's very little that's wider than 12".

Basically the vast majority of 4/4 lumber is 5" to 7" wide. Thicker lumber, such as 8/4, is often mostly 7"-10".

12" or wider is no problem in some woods in some thicknesses.

But the majority of hardwood lumber in 4/4 thickness is less than 12" wide. The majority. It's not impossible to get 12" or wider lumber, it's just not the norm. You may specify 12" or wider widths, and if we can accommodate your request we will do so.

If it's not, we must ask: what's your project? Are you opposed to gluing up for some reason? Need us to glue it up for you? We can do that, too.

However, understand that there's no guarantee we can provide it at all times in all woods.

Woodworking is basically three procedures: cutting, shaping & gluing. So, the tried-and-true way to get super-wide solid wood is to glue it up from narrower boards, then trim it down to the required size.

If you absolutely must have wide boards that aren't glued up, you should ask yourself why is this necessary?

Warnings About Solid Wide Lumber

The wider the wood, the more likely it will contain defects.

Wide solid wood will not stay flat. All solid wood expends and contract as it equalizes with its environment. The effect on wide wood is even more pronounced due to the greater number of wood fibers.

Building with wide solid wood requires some knowledge in how to accommodate wood expansion and contraction (read: wood movement cannot be stopped so learn to work with it) See our tips and discussion for wood movement on this page

There Are Other Ways to Create Wide Panels

Shelving, desk tops, chest lids, conference tables, and cabinet doors are just some of the projects that call for wide panels. Solid wood works as long as you know what to expect and how to deal with wood movement.

But you can save time and money by using:

- High quality veneered plywood

- Veneered panels made in your shop

Plywood can be treated with a solid wood edge that 1). allows you to rout a decorative profile, and 2). can provide the appearance of a 2" or 3" or thicker panel without the weight, the cost, and troubles of a solid wood panel of the same size.

Veneer can be purchased in numerous varieties of wood, and choices like burls and figured woods are much higher and consistent in quality than what you can routinely find in solid wood. Veneer can be applied to a plywood substrate and also treated with solid edge to create the appearance of a thicker panel.

Creating wide solid wood panels with glue and clamps is a routine procedure in woodworking, and a safer bet than hoping to buy super-wide solid wood from your lumber supplier

Yes we can.

Tell us what you're trying to acheive, or what your final finished size is, then we can see if what we have on hand will accommodate it. Please be sure you're clear about what you need or expect, too.

It's not uncommon for customers ask for sizes that they wish to start with rather than what they want to end with - and this creates more problems than solutions. Understandably, you might think you're going to save money on wood by doing it this way, but it's the wrong way. Tell us what you need to end up with, we'll tell you what we've got that can accommodate it.

We're on the same team as you. We want to you build a great project and we want you to be happy with what you buy from us. We're here to work with you.

Yes, we can cut to size for you. But we can't cut joinery.

Remember, if you can do your own cutting to size, there's no need to pay us to perform custom cutting for you.

When talking about sizes, it pays to be absolutely clear about what you need:

- Do you need custom cutting to finished size?

- Or do you need custom selection so you can cut to particular sizes?

A custom selection means we will sort and select lumber that will allow you to cut down to your finished size. Sizes will still be random and not uniform , but they will exceed your minimum size demands.

See our answers about available widths and lengths.

Charges for Cutting To Size

We can quote your project. Basic shop charges start at $15 minimum.

Send us your list and we will provide you a quote.

But be aware that building a woodworking project requires you to be able to perform on-the-fly precision adjustments. Such as with fitting joinery together. If you have someone else cut your parts for you, you still need to be able to finesse your project together. Trim to length, square up the corners, finish sand, finesse to fit, etc.

Actually, we do have some dimensional lumber. Check out our Hobby Boards and Turning Squares . These are woods cut to uniform sizes that might work for you.

But let's discuss hardwood lumber and why it's random in size. The hardwood industry aims to serve furniture makers, cabinetmakers, artists, and other types of custom craftsmen. And because of that, their projects are frequently custom -- that means there are no standard sizes that will work for everybody. So, selling wood that's been processed down into uniform sizes only adds needless labor, machining, waste material and therefore cost.

Random sizes are also a matter of practicality. Trees are roundish and random in size, too. So the lumber each tree yeilds is random.

Food For Thought

Why pay the extra cost for pre-cut dimensional sizes if you're just going to cut down to whatever your project needs anyway? Random will do, and random will cost you less.

Lumber Basics

We suggest you kick back and watch the video above.

Basically? The way hardwood lumber is bought and sold doesn't make any sense when you're new to this stuff and you're probably thinking, "why does this have to be so confusing?"

Fret not! We're here to help - start with the video.

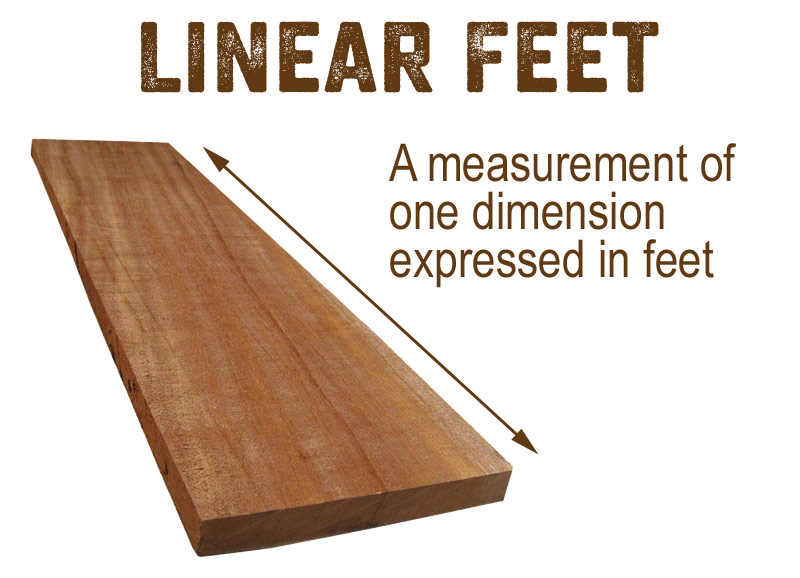

Linear Feet

A measurement in a straight line. Linear footage measures just one dimension.

This is the unit of measurement to use when buying or selling wood that's cut to standard or uniform dimensions.

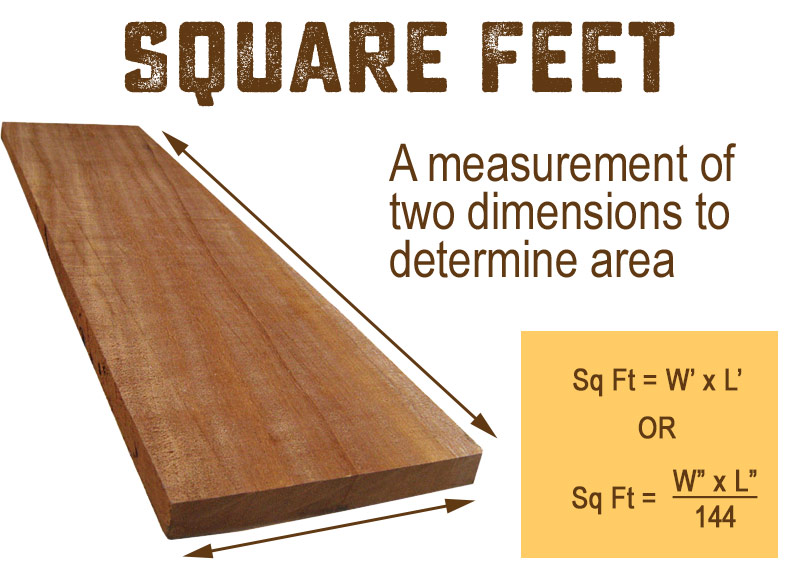

Square Feet

A measurement of area. Square footage measures two dimensions.

This is the unit of measurement to use when buying or selling lumber that's less than 1" thick.

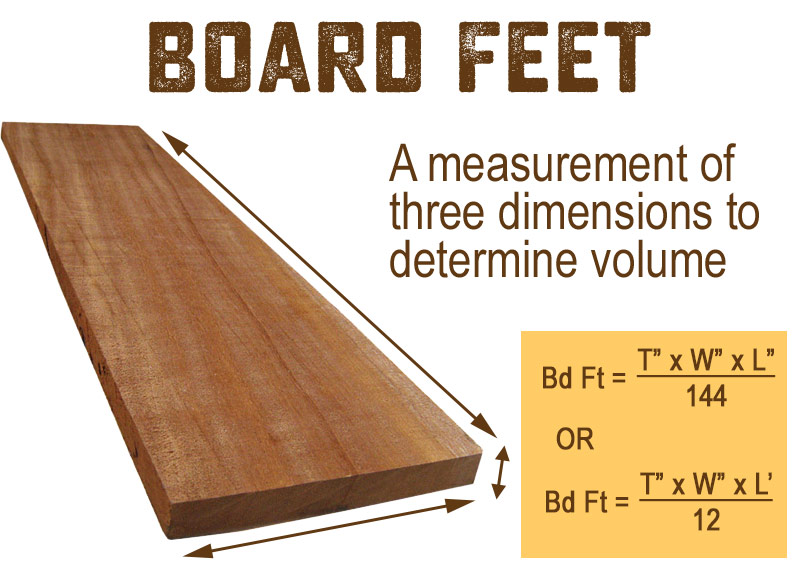

Board Feet

This is the unit of measurement to use when buying or selling lumber that's random in width and length. Since boards are various in size, board footage is the fair way to determine the amount of wood in variable sizes.

NOTE: When figuring board footage of a board, here's how you measure:

- Measure the width to the nearest 1/4"

- Measure the length to the nearest whole inch

- Thickness is not measured. Instead, use the thickness name regardless of the actual measured thickness. For example, when measuring 4/4 use 1" even if the actual measured thickness is 13/16"

Here's what we suggest you do:

- Make a list of your project parts

- Calculate the board footage of each part

- Add up the footage for each part (but separate into groups so you know what needs to come from 4/4, 8/4. etc)

- Multiply each sum by a waste factor of at least 1.5

Me & Math Don't Get Along - Give Me Another Way

Download our Project Planner worksheet. Just fill it in with your project parts and it'll do the hard part.Check out our video tutorial on how to use it, too.

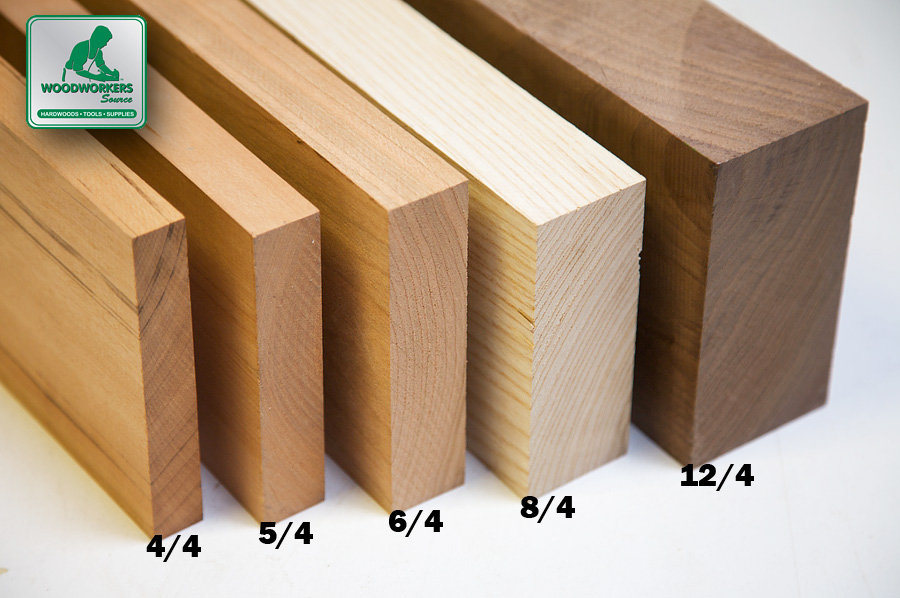

This is a fraction. It identifies the thickness of wood.

- 4/4 means approximately 1" thick

- 5/4 means approximately 1-1/4" thick

- 6/4 means approximately 1-1/2" thick

- 8/4 means approximately 2" thick

- 12/4 means approximately 3" thick

There are some nuances to the precision of this fractional name. So, read a more in-depth discussion in our blog if you're curious. .

Select & Better Lumber is *usually* virtually clear on one side. By definition it must be at least 83-1/3% clear of defects on its best face.

Sadly, hardwood lumber can't be guaranteed to be absolutely free of defects 100% of the time.

Instead, hardwood lumber is sorted into various grades that guarantee a minimum percentage of clear, defect free wood. Grades are determined by the size of the board and the percentage of clear wood in the board. Size of board matters? Yes - think about it. A large clear board is more desireable than a small clear board.

These grades are not invented by Woodworkers Source, instead the rules and guidelines are set for the hardwood industry by the National Hardwood Lumber Association. The highest, best grade is called "FAS" and promises to be 83-1/3% clear on the poorer side (lumber has 2 sides, only one side determines the grade).

However, in practice FAS graded lumber is rarely available to buy from lumber producers. Instead, what a lot of wholesale lumber producers do is mix the top three grades (Select, F1F and FAS) and call them "Uppers" or "Select & Better" and sell it that way.

Select & Better lumber is the best grade that's available day in and day out. And most of the time it qualifies as "Better."

Firsts and Seconds (FAS)

The best and most expensive grade. Boards 6" and wider, 8' and longer. Yields 83-1/3% of clear face cuttings with minimum sizes of 4" x 5', or 3" x 7'. Board is graded from the poorer face.FAS One Face(F1F)

The same as FAS except the board is graded from the better face.Selects(SEL)

The better side grades FAS, but back side grades No. 1 Common (or better). Boards are 4" and wider, 6' and longer. Yields 83-1/3% clear face cuttings with minimum sizes of 4" x 5', or 3" x 7'.

We stock "Select & Better" (a mix of all three of those grades), unless we're talking about our knotty or rustic lumber choices.

Want to dive in even more? Click here for a full explanation of hardwood lumber grades.

We have an awesome page with our best suggestions right here

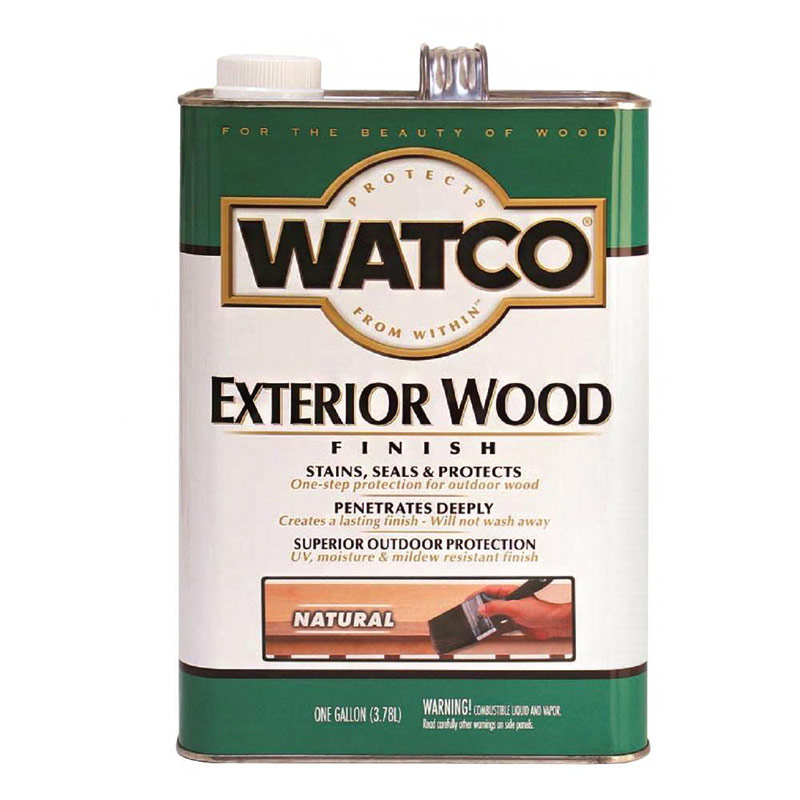

Sunshine and precipitation are hard on wood. Regardless of the kind of wood you choose, you should take measures to protect your projects from repeated exposure to sun and water.

Choose a Protective Wood Finish

Exterior Oil: we like to recommend exterior oil for projects like patio furniture, adirondack chairs, tables, potting benches, etc. The oil needs to be reapplied once or twice a year, but it's a nice looking finish that repels water and is very simple to rejuvenate with a fresh coat without stripping the previous coats.

Marine Spar Varnish: this thick clear wood coating is just as suitable for furniture, but it's mostly used on things like exterior boat trim. This kind of finish can go longer without maintenance (unlike exterior oil). But maintenance on a spar varnish usually means sanding & stripping it off, then re-applying.

Exterior paint: no coating or finish protects wood as long as paint does. The downside is that it hides the warmth and beauty of wood. When that's not an important factor to you, choose paint.

We have an awesome page with our best suggestions right here

Did You Know?

You can use virtually any wood you want. There aren't any that are absolutely dangerous or toxic.

Irritants and sensitizers in wood really come from bark and dust - but solid wood is benign. That includes exotic woods. But some are more suitable to take the abuse a cutting board will endure.

Lumber packs include the shipping costs to any state west of the Mississippi River, whereas lumber by the board foot doesn't include shipping at all.

Why the Mississippi River? Our shipping warehouse is in Phoenix, Arizona. Sadly, the farther you live from us, the more it'll cost to ship to you. It's not personal. The Mississippi is basically a point at which the rates we incur increase substantially. That's why on these packs we add on a flat surcharge to destinations east of the Mississipi.

Maybe. If we have it, you will find it using the site search.

Special order? Try us. It never hurts to ask. But there are some nonstarters.

- Small quantities - It's difficult to special order just one or two small pieces of a wood. To get the interest of our suppliers, we need to be looking at a quantity usually of at least 100 board feet. But there are some exceptions.

- Non-commercially harvested wood - Fewer than 300 species of trees (out of a worldwide estimate of 100,000+) are actually harvested for their wood and allocated through the business chain of distribution.

- Wood from "country X" - Easier said than done. A lot of times species grow in regions that span several countries. For example, the mahogany species Swietenia macrophylla is historically called Honduras Mahogany even though it grows virtually in every country between Mexico and Argentina. But it's not always harvested in or exported from each country. For that matter, it's no longer harvested in Honduras. That's just to give you an example of the difficulties of trying to buy a certain species from a specific part of the world.

- Bark, sticks, or leaves from "species x" - We sell wood.

- Endangered species - Forget it.

Shipping Lumber

To find out, we need to know what you want to have shipped and to where.

We pass along the actual cost the carriers charge us. But we do get very good rates thanks to the volume of shipping we do.

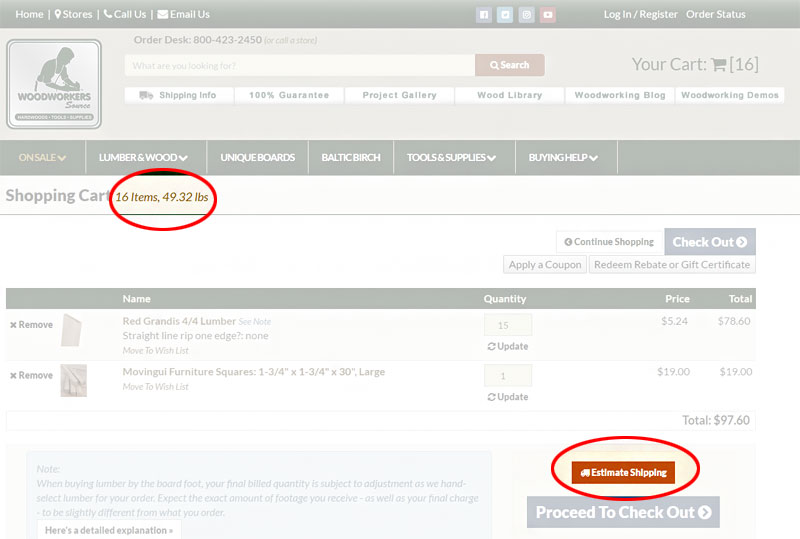

2 Ways to Get a Rate

- Add items to your cart then click "Estimate Shipping"

- Call or email the Help Desk to ask for a quote

To get you an accurate quote, we need to know 3 things from you:

- Quantity of lumber/product

- Shipping destination

- Special requirements for lumber sizes, and/or special requirements for delivery

Some of our products include shipping or have a simple flat rate, which is clearly stated on the product's page.

On other products, shipping charges are determined by FedEx, USPS, or a truck freight carrier, depending on the size of the order in question.

Tips for getting your best shipping rate

- Pay attention to the order weight. The highest (worst) shipping rates occur 1 to 5 lbs, and 71 to 79 lbs

- The best rates occur between 60 and 69 lbs (for FedEx shipments)

- Go bulk! Shipments of 150 lbs or more get the absolute best rate-per-foot. You get more wood for your dollar than you do with smaller shipments.

Shipping a quantity of 1 of any kind of wood, veneer, or plywood is very inefficient. Try adding a couple more pieces to your cart and then run the shipping estimator. You'll see that your shipping charge barely changes, yet you're getting more wood.

84"

UPS or FedEx Ground72"

USPS Domestic24"

USPS International14 Feet

LTL Truck FreightMost shipments go through FedEx. The longest lumber we can reasonably ship by ground services is 84". However, they do accept larger packages and they charge a very significant premium.

Therefore, you can get 7' long lumber by FedEx standard ground without excessive shipping fees.

Shipping longer lengths is possible by LTL truck freight - see the next question.

Yes. Long length lumber must be shipped by a truck freight carrier.

Two Things to Know About Truck Freight Shipping

First: the shipping rates aren't very economical unless you're shipping 150 lbs or more. That's about 60 board feet or so (depending on the wood).

Second: truck freight delivery comes with a different level of service than you might be used to with is a UPS, FedEx, or USPS package delivery. Truck freight means someone at the delivery location must be available to unload the truck.

We do what it takes to make this easier on you, though. We'll wrap your lumber in smaller bundles you can manage by hand, then strap & wrap those to a pallet. That way you can clip the straps then unload one bundle at a time.

Hardwood lumber shipped on a pallet to your home can be wrapped like this: wood wrapped in bundles approximately 60 to 70 lbs each, all strapped to a pallet and wrapped for protection. The individual bundles make it easier to unload by hand if you don't have a forklift to off-load the truck.

Hardwood lumber shipped on a pallet to your home can be wrapped like this: wood wrapped in bundles approximately 60 to 70 lbs each, all strapped to a pallet and wrapped for protection. The individual bundles make it easier to unload by hand if you don't have a forklift to off-load the truck. Yes!

There are limitations on size. Usually the package may not exceed 36" in length. Please contact us to get a shipping quote.

Because you're hiring someone to hand deliver heavy, awkward packages right to your door.

Here Are Some Tips:

The worst shipping rates occur between 1 to 5 lbs, and 71 to 79 lbs. We post the weight of your order right in the "View Basket" screen to help you make an informed decisions on how, if at all, you might want to adjust your order.

Shipping small amounts, like just a couple of small pieces, is not usually economical. Shipping larger amounts of at least 150 lbs yields the best shipping rate.

Size is another factor. Small package carriers like UPS, FedEx, and USPS charge extra fees on top of their weight rates for packages longer than 48" (and even more for packages longer than 96"). Sadly, a lot of furniture projects require length. If you can handle lengths shorter than 45", often we can get you a better shipping rate if you let us know.

We charge you exactly what the carrier charges us. Shipping rates come directly from UPS, USPS, or a truck freight carrier (depending on the size of the shipment).

Possibly. Take a look at the weight of your order in the "View Basket" screen.

If your order is under 70 lbs, try this:

- Check the shipping charge using the "Estimate Shipping" button

- Change your quantities to get as close to 70 lbs without going over 70 lbs

- Now check the shipping charge. How do the two rates compare? The amount may have increased by a small amount, but you're getting more wood for your dollar.

If your order is over 70 lbs, try this:

- Shipping rates between 71 and 80 lbs are pretty steep.

- Increase your quantities to be closer to 150 lbs, or decrease quantities to be between 60 and 69 lbs.

If your order is over 150 lbs

Call or e-mail us! We can often get a better rate for heavier orders like this by checking different shipping carriers, and we're happy to do it.

It depends where you live. We ship from our beautiful warehouse in sunny Phoenix, Arizona.

Check this map for a basic idea.